Energy, Power, Transportation I

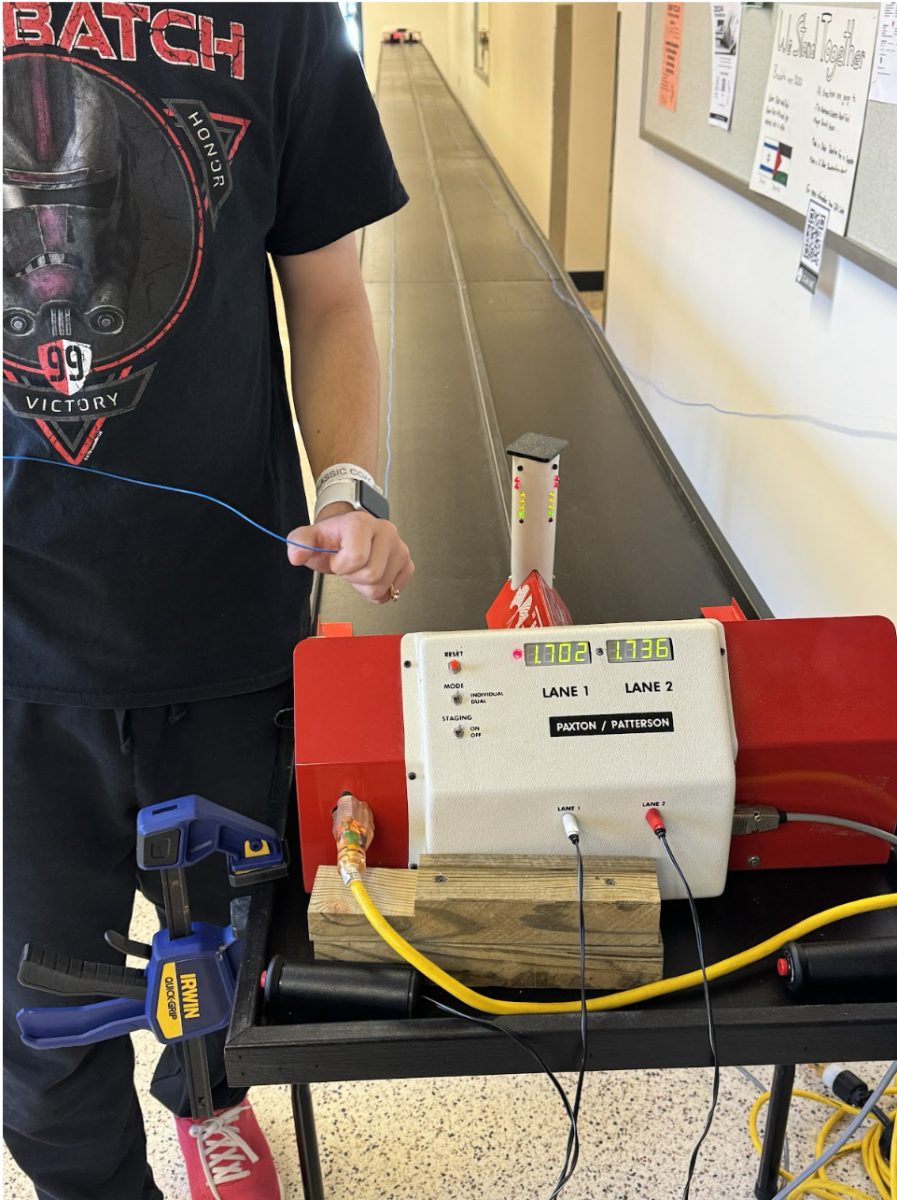

Students in Energy, Power, Transportation I class taught by Mr. Ondayko constructed and designed wooden cars for a bracket elimination race against each other. The Energy, Power, Transportation I class is a relatively new class at the high school, introducing many different challenges and competitions that the students have to overcome while building effective designs to combat the hardship of the challenge: propelling the car forward with CO2 gas, or carbon dioxide.

“In this assignment, students are learning how aerodynamics affect vehicles and how weight, friction, and mass affect the speed and efficiency of a vehicle,” said Mr. Greg Ondayko. “The racing aspect will measure their times.”

C02 racing cars are propelled by a carbon dioxide cartridge that is punctured so the compressed gas can rapidly leave the canister, causing the car to move so it can race on a typically 60 feet track. This assignment demonstrates mechanical principles such as mass, force, acceleration, and aerodynamics, while also encouraging competition among the students.

“For materials, the cars are made out of balsa wood,” said Ondayko when asked about what the cars are made from. “Materials other than that were steel axles and plastic wheels.”

Each car was constructed and modified into different shapes and sizes to be raced down a straight track ranging from room 105 down to about the Guidance Office on the first floor of the high school.

Students in Ondayko’s class also built cars in Auto Computer Animated Drawing (CAD), showing two views of the design of the car. Students also used a CNC router, a design material that uses computers to control a machine that cuts various objects, to manufacture the car. According to Wikipedia, a CNC router is defined as a “computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.” This structure was used for designing the cars before the students tested their speeds and competed against each other.

“For my car, I cut out the entire center and modified it to make it as light as possible,” said senior Tanor Benco. “I took some inspiration from cars I saw online while doing some research on what was the lightest and most aerodynamic car and put my own spin on it.”

Students faced several difficulties in the process of constructing their car, however. It is often difficult to come up with a design that will efficiently propel the vehicle forward while also not malfunctioning in the process.

For students, the idea of the design was to create a vehicle that was fast and effective. However, during the design process, many students were worried about the weight of the cars bringing the speed down.

“What was challenging for me was balancing the weight and aerodynamics of my car,” said Benco.

After the competition, where students competed against each other by racing their different CO2 car designs, senior Tanor Benco finished first on the period 3 bracket while sophomore David Boyer finished first on the period 4 bracket.

Now what exactly does the winner of the contest get? Although there was no set prize, like money or a small gift from Mr. Ondayko, the students who won enjoyed bragging to others about their recent win. Benco and Boyer won first place for each respective class, and enjoyed bragging to others about their design skills and their overall win in the competition.

“Usually just bragging rights” said Ondayko. “The grades aren’t really tied to students winning or losing, it’s more just a fun concept in the class.”

Along with designing cars to propel using carbon dioxide gas, Mr. Ondayko’s students will also design maglev vehicles, cable cars, and design various inventions using the CNC design method.