Positive Potential

Norwin senior Joe Zaradzki creates and distributes custom batteries under his business, Z Battery Solutions LLC.

December 13, 2021

The novel concept of high school students becoming entrepreneurs has quickly become a trend or fad on par with any dance off of TikTok. Between the easy accessibility to investment apps such as Robinhood and Vanguard, reselling products from Goodwill through Facebook or eBay, and now buying and selling NFTs through OpenSea, everyone and their mom can be classified as a business-savvy “entrepreneur.” Very few students can truly claim they have started a business from the ground up.

Norwin senior and battery aficionado Joe Zaradzki is the founder, owner, CEO, president and director of Z Battery Solutions LLC., a custom battery company that provides anything from custom battery packs to high power batteries for electric skateboards, and even a line of merchandise.

“All of this started with wanting to build an electric skateboard, and that idea started long before all of this,” Zaradzki said. “I believe it was watching Casey Neistat zoom around NYC on his Boosted Board in his vlogs. The problem is boosted boards (before they went out of business) were $1,500+ and I had nowhere near that much to spend. So my solution was to build my own for cheaper (which wasn’t really cheaper in the end).”

Now 17, Zaradzki has been working on building up his battery repertoire for over two years.

“I designed my first battery in fall 2019,” Zaradzki said. “I’ve worked with small RC cars and drone batteries before then, but this was my first substantial battery. The first battery I designed for my business was in January/February this year.”

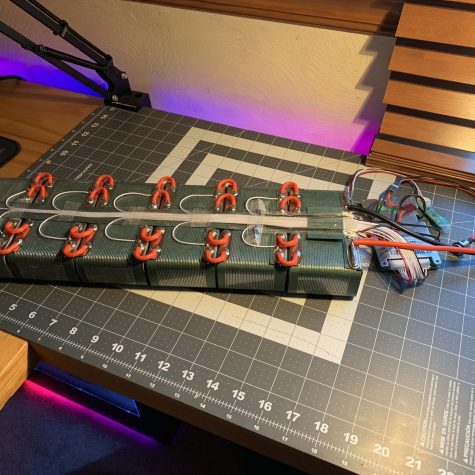

Building custom lithium-ion battery packs is no small feat, as one would imagine, and it’s quite expensive too. Zaradzki had to run at a loss before being able to monetize his passion.

“To build a battery you need a lot of equipment and materials,” Zaradzki said. “Just the spot welder required to join the individual battery cells is $400. After adding it all together, I spent nearly $800 on a basic set of equipment to build a few batteries, and that didn’t include the battery cells themselves. I needed a way to pay off that initial investment, so I figured I’d build a few for other people to pay it off.”

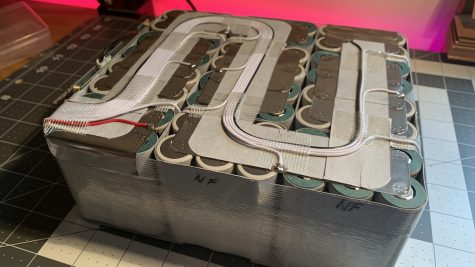

Zaradzki broke down the process of how to build a custom battery pack.

“Just like how living things are made up of many individual cells all working together as one being, a battery pack works in the same way,” Zaradzki said. “I buy the individual battery cells, and assemble them to create one big battery. There are sensors all over just like nerves, and an electronics system that acts as the brain.”

The designing process of custom battery packs begins with the customer. Zaradzki has his website set up so that those who know exactly what they want can directly message him with the parameters of their battery needs.

“The purchasing process starts by the customer messaging me with what parts they have in mind and how far/fast they would like to go,” Zaradzki said. “Then I’ll give them some options they can choose from. Once they decide, I send an invoice and start the build. Throughout the process I’ll send them pictures and at the end send QC test results. Then it goes off to UPS and to the customer for them to install.”

In between AP classes and band practice, Zaradzki is hard at work making sure the gears keep running for Z Battery.

“In most of my free time during the school day, I’m usually answering emails and talking to manufacturers about sourcing materials,” Zaradzki said. “Especially with all the shortages that are happening, I have to spend a lot of time doing this. In the afternoons and weekends, I spend most of the time actually building the batteries. The average custom battery may take 8-12 hours to build, but that can change drastically so I usually have to split it into 5-6 hours a night.”

Zaradzki broke down how his business initially began.

“The selling basically turned into a business on day one,” Zaradzki said. “Due to the fact that lithium ion batteries are extremely dangerous, I needed to form a limited liability company as soon as I started. The customers are installing these batteries in devices that they’ve built themselves, so if they do something wrong and blow themselves up, they can easily blame it on me. This has happened due to a customer opening the battery up and trying to modify it. Luckily, he admitted it was his fault and I was able to repair it.”

Zaradzki admitted that though battery designing is a fun and productive use of time, you have to be extremely careful with the assembly process.

“The problem is that they have to be assembled perfectly or you end up with an explosion,” Zaradzki said. “Most people do not have the time or skill to make a battery themselves, so they purchase them from me.”

Though custom batteries may seem like a niche market, Zaradzki has found an online community that shares this common interest and helps one another out.

“There is a whole community of people on a website/forum called Esk8.news that are extremely knowledgeable about electric skateboards and batteries,” Zaradzki said. “I’ve learned everything about batteries from there, and they have some of the best DIY battery builders and resources in the world. Every time I had a question, they would reply instantly in great detail. Nowadays I am one of those people, helping out new builders.”

Zaradzki was also helped by many people in his personal life.

“Outside of that community, my parents helped a lot with lending me money in the beginning, and my cousin who is an attorney helped me set up the LLC. and legal documentation,” Zaradzki said. “Joey Secosky helped me design my logo, merch, and a little bit of the website.”

While many may set aside their hobbies and interests when they begin to transition to college, Zaradzki shows no signs of slowing down. The future of ZBattery Solutions seems bright.

“Recently I started working with a company called Silent Electrics that builds electric power systems for ultralight planes,” Zaradzki said. “They hold 1-2 passengers and can fly for hours at a time. I build the battery packs and they design the electronics and motors.”

As most seniors transition to college, the fear of future job stability continues to grow. Zaradzki, though, can be “positive” about future career opportunities, whether it attributed to his outstanding resume or continued success from Z Battery Solutions.